Loading... Please wait...

Loading... Please wait...- Home

- ThermalPower

ThermalPower

RAMSOND Corporation is steadily growing to become an elite provider and manufacturer of turbine parts and power generation systems and services. Founded upon the basic principles of high quality service and immediate dispatch, through innovative solutions and logistics planning, Ramsond Power Generation Division can accommodate all power generation needs of a variety industries and customers.

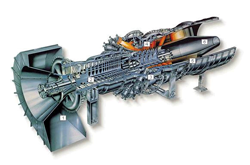

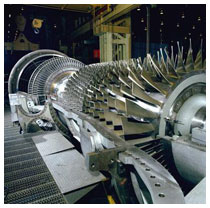

Whether you have an immediate and urgent need for a set of first stage buckets for dispatch to your GE Frame 9 turbine (also Frame 5, 6, 7) or require a set of complete compressor blades, in most cases, Ramsond can deliver the needed parts to its final destination, within 24-48 hours. Through our established affiliations, we can also provide a wide range of turbine field services including inspections, analysis, design, management and consulting. In addition to manufacturing, re-engineering and modifications of gas turbine parts, such as buckets, nozzles, liners and casings, Ramsond also provides for the most expedient repair and/or replacement services for all component parts such as buckets/blades, nozzles/vane segments, shroud blocks, combustion parts such as liners/baskets, transition pieces, cross fire/flame tubes, etc. Ramsond also has the capability to repair/replace/recondition/upgrade modern turbine rotors of various sizes and weight are repaired and overhauled which includes disassembly, cleaning, NDT and dimensional inspection of all turbine parts. Following repairs, complete assembly is also performed. Please complete a submission form below and one of our service personnel will contact you immediately to assist you:

Combustion turbines have been used for power generation for decades and range in size from units starting at about 1 MW to over a 100 MW. Units from 1-15 MW are generally referred to as industrial turbines, a term which differentiates them from larger utility grade turbines and smaller microturbines. Combustion turbines have relatively low installation costs, low emissions, high heat recovery, infrequent maintenance requirements, but low electric efficiency. With these traits, combustion turbines are typically used for cogeneration, as peakers, and in combined cycle configurations.

|

What renders Ramsond’s services unique and in class on its own is its ability to provide expediency of service and immediate dispatch. Not only we can provide OEM and RE (reverse engineered) components for rare turbomachinary products, but we stock, FOR IMMEDIATE DISPATCH AND DELIVERY, some of the most demanded, consumed and urgently needed spare parts for a variety of brands of gas and steam turbines, such as GE, Hitachi, Siemens, Etc. Ramsond’s logistics planning and inventory management system combined with it completely integrated service plan, can dispatch, not only routinely required parts, such as blades, buckets, vanes, nozzles, combustion liners, transition pieces and other immediately required components, but also can expeditiously commission the manufacturing and/or reverse engineering of some of the more rare or non-stock components.

What renders Ramsond’s services unique and in class on its own is its ability to provide expediency of service and immediate dispatch. Not only we can provide OEM and RE (reverse engineered) components for rare turbomachinary products, but we stock, FOR IMMEDIATE DISPATCH AND DELIVERY, some of the most demanded, consumed and urgently needed spare parts for a variety of brands of gas and steam turbines, such as GE, Hitachi, Siemens, Etc. Ramsond’s logistics planning and inventory management system combined with it completely integrated service plan, can dispatch, not only routinely required parts, such as blades, buckets, vanes, nozzles, combustion liners, transition pieces and other immediately required components, but also can expeditiously commission the manufacturing and/or reverse engineering of some of the more rare or non-stock components.